Exhibition 2018

Catalyst technology for the gasoline engine cars

Exhibition 2018

"Most of the cars focusing on fuel efficiency have an idling reduction function that engine stops during waiting at the traffic light. But a problem is to emit harmful NOx gas at restart of the engine. We have worked on the development of a new material for the purpose of reducing NOx emission at engine restart."

"To make it short, the exhaust gas purification catalyst (hereinafter called automotive catalyst) is the high heat-resistant material that precious metals are applied to. The precious metals purify and reduce the harmful gas (CO: Carbon oxide, HC: Hydrocarbon, NOx: Nitrogen oxide) that is contained in the exhaust gas from automobiles. Automotive catalysts have to be designed to promote stable purification reaction even in a high temperature environment at over 1000℃. "

"Automotive catalyst consists of two functions that precious metal (Pt: platinum, Pd: palladium, Rh: rhodium) to be a key to purify harmful gas and the base material (substrate) to supportprecious metal. The substrate is made from complex oxide such as Zr: zirconium and Ce: cerium and the accessory component is added to meets the purpose of suppressing sintering of precious metal."

"Direction of the automotive catalysts development differs by atmosphere of the exhaust gas. Optimum catalyst is depending on the engine because the atmosphere of the exhaust gas depends on the engine control. Optimum catalyst development is required especially for the idling reduction cars that are in widespread use in recent years because they are totally different in engine control compared to the conventional cars. "

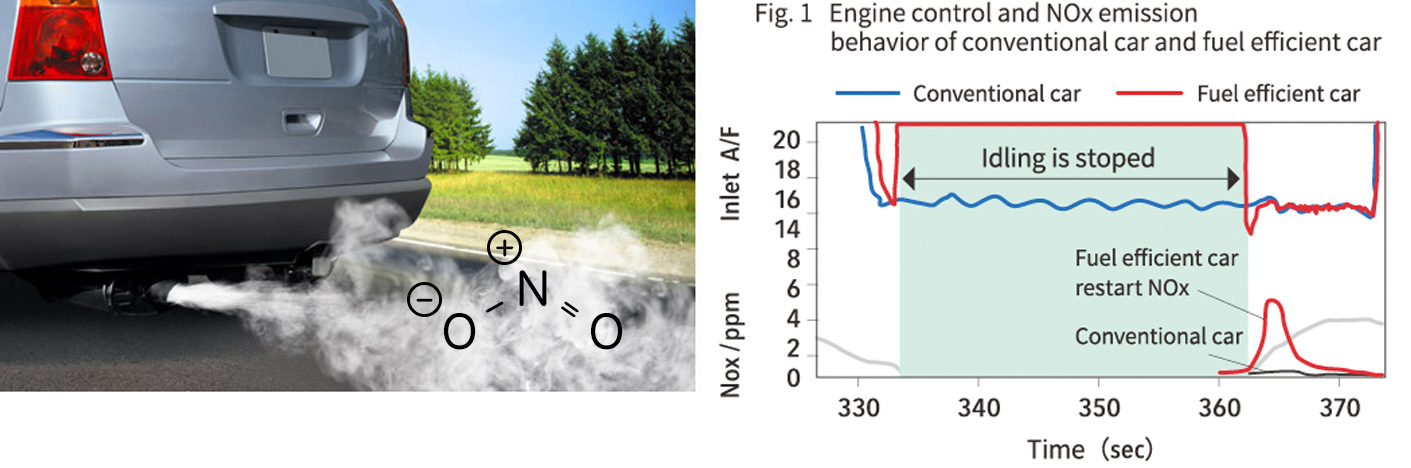

"Conventional cars keep the engine running during the car is stopped. This is called idling and it uses gasoline little by little. On the other hand, the engine of the idling reduction cars that are becoming popular stops when the car stops to wait at the traffic light and it restarts when the driver steps on the accelerator to drive. The idling reduction cars emit NOx when restarting. (Fig. 1)"

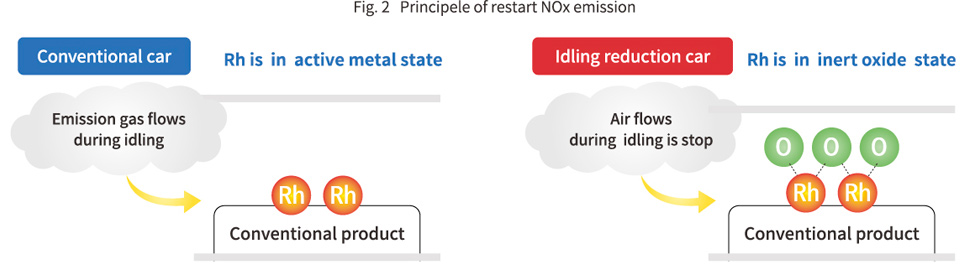

"When the idling reduction cars restart the engine, gas atmosphere that flows into the catalyst changes due to difference of engine control and that causes the NOx emission. During the conventional cars wait at the traffic light, precious metal condition in the catalyst is active because the engine keeps idling and gas atmosphere in the system doesn't change. On the other hand, the idling reduction cars stop engine during waiting and precious metal becomes inert oxide due to air flows into the catalyst.(Fig. 2) If the engine restarts in that condition, exhaust gas flows into the catalyst and it causes NOx emission."

"Element such as cerium oxide (CeO2) and lanthanum oxide (La2O3) are added to zirconium (Zr) oxide in the material (Substrate) used for automotive catalysts. Precious metal is loaded in the substrate to purify harmful gas and its characteristics changed depending on the composition of the substrate. We made effort based on the concept of suppressing deterioration of precious metal in existing catalyst development and the purpose of it was to prevent precious metal deterioration with stabilized base material by adding element that improves heat resistant to zirconium oxide. We have developed from the viewpoint of improving purification performance by changing characteristics of substrate which is the base material but not suppressing precious metal deterioration."

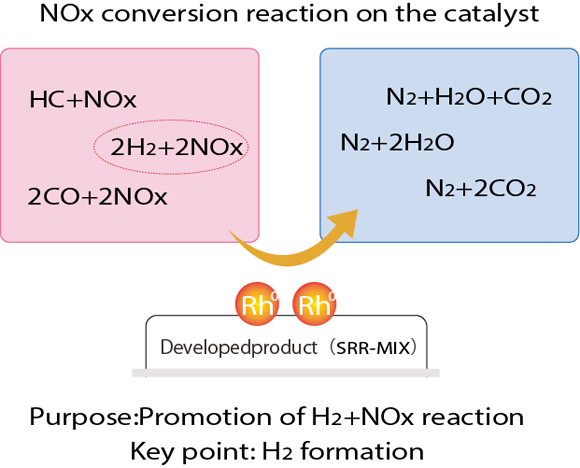

"Reducing agent to reduce Knox is necessary to purify NOx. But the purification right after the engine restart doesn't catch up with even the reduction gas flows in the catalyst because the catalyst on the idling reduction car is in oxidation atmosphere when engine stops. We started development with an idea that ""Isn't it possible to generate reducing agent to reduce Knox at the same time of purifying NOx."

Two different reduction reaction such as of hydrocarbon (HC) and carbon monoxide that are the same harmful gas, and with hydrogen (H2) at NOx purification reaction in the exhaust gas from vehicle. We focused on H2 that had the highest performance of reduction and have researched additive elements to promote reaction for generating H2.

Compare the elementary reactions that are promoted by adding various elements and find the element that can obtain target effect then add to material. The catalyst using that material was evaluated by actual cat test.

※Elementary reaction is the individual basic reaction that constitutes chemical reaction.

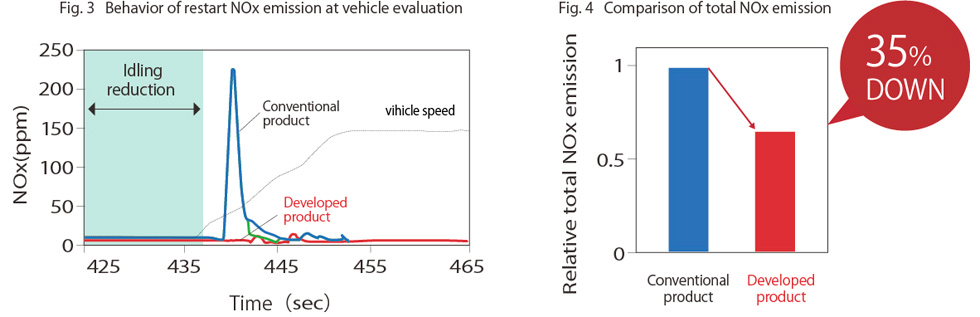

"As a result of comparison of exhaust gas amount at re-start engine after stop idling between existing catalyst and the catalyst using the Restart NOx emission suppression material (SRR-MIX) by actual car test, it was found that the catalyst with the Restart NOx emission suppression material (SRR-MIX) could suppress NOx emission at re-start engine. In addition, total amount of NOx emission was reduced by 35%. (Fig. 3, 4) Emission gas regulations will become stricter more than ever every country in the world. Moreover, it is expected that the car type such as Plug-in hybrid vehicle (PHV) which is the assemblage of the hybrid vehicle (HV), gasoline engine car and electric car will become widely used. The environment surrounding the automotive catalyst is estimated to change significantly in the future. In such a circumstance, we need to continue developing new materials with our skills which have been cultivated. We will conduct more detailed analysis of SRR-MIX and lead to the development of new material applying the analysis result."

※"SRR-MIX" is a technical name, it is not a product name.