Exhibition 2018

Catalyst technology for the diesel engine cars

Exhibition 2018

We have developed a catalyst technology for DPF, that forms mesh type catalyst layer over the cell walls on the exhaust gas inlet side of the Diesel Particulate Filter (DPF).

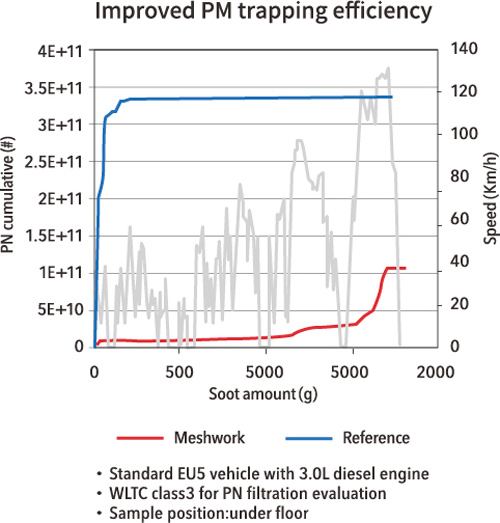

We have achieved 68% reduction of particle number (PN) of the particulate emissions compared to it of the existing catalyst.

"One of the substances emit from the diesel engine is PM, the particle matter. PM is subject to an emission regulation of diesel engine as well as the nitrogen oxide (Knox). Particulate matter is suspected of causing respiratory disorder, allergy or cancer and that is why the particulate matter is the cause of air pollution."

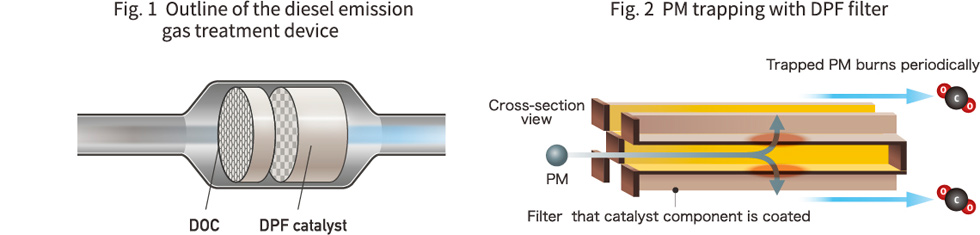

This is the filter device that filtrates and removes particle matter (PM) in the exhaust gas from diesel engine cars.

DPF traps PM in the exhaust gas in the fine pore structure on the substrate walls and the trapped PM accumulates in the DPF pore with time. Therefore DPF regeneration is necessary for removing accumulated PM periodically by burning at high temperature.

To coat catalyst on DPF is under consideration in order to burn PM at lower temperature and shorter time as much as possible at DPF regeneration.

Our catalytic technology for DPF (Meshwork Catalyst) has successfully burned more PM within the temperature range from 560℃ to 570℃ compared to existing catalyst for DPF.

As was mentioned earlier, the diesel particulate filter that can trap PM is necessary for exhaust gas purification system of the diesel engine cars.

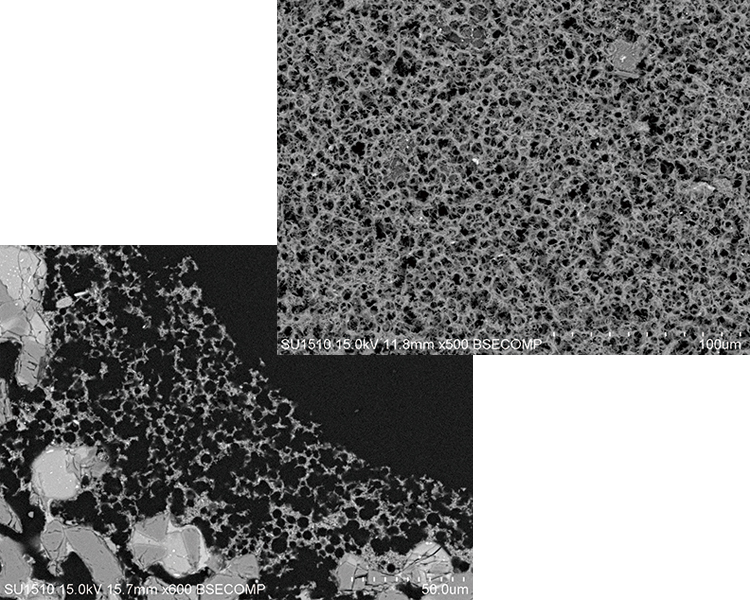

Structure of cell walls of the DPF substrate is porous and PM is trapped in the DPF by

filtration in the cell wall.

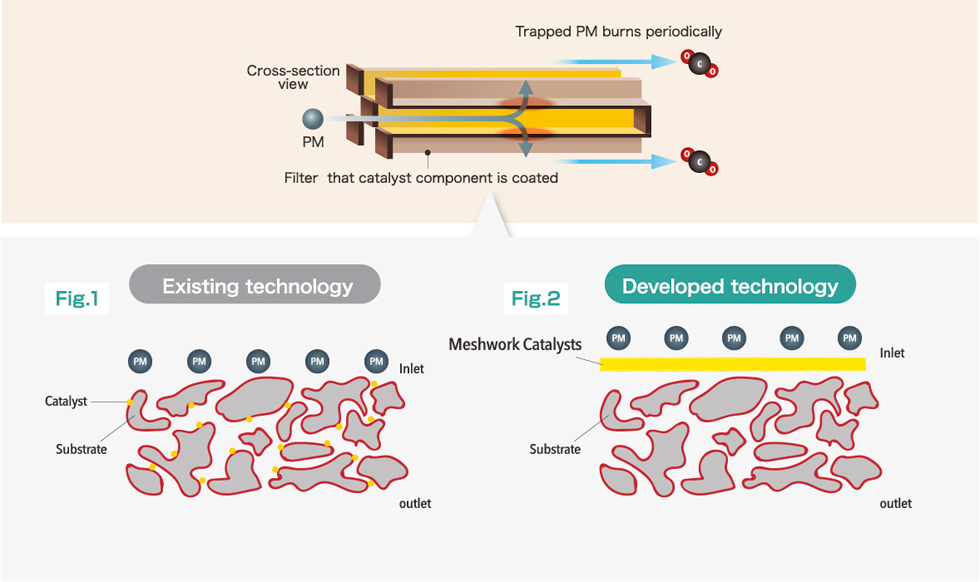

Catalyst component is coated in the pores on the DPF cell walls in order to promote combustion of trapped PM when DPF recovery. (Fig. 1: Existing technology)

In recent years, air pollution due to particle matter (PM) from diesel engine cars is becoming more serious.

In addition, PM is considered a substance that negatively impacts on the human body not just on the environment protection of the earth. Therefore, stricter regulation of PM emission amount reduction has come into force in each country including Europe.

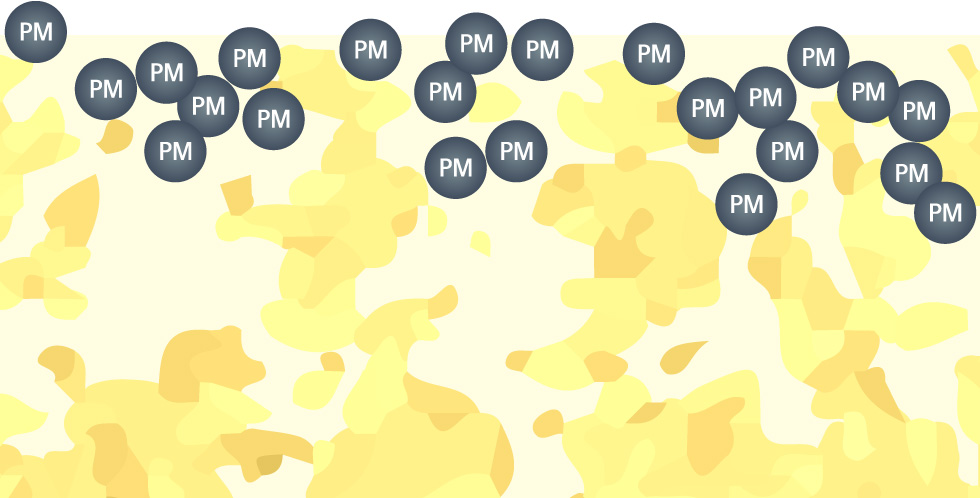

Under the circumstances, we have developed a catalyst technology for DPF to improve PM combustibility by forming mesh type catalyst layer(Meshwork Catalyst) which has unique pore structure over the cell wall on the exhaust gas inlet side of the DPF. (Fig 2: Developed technology)

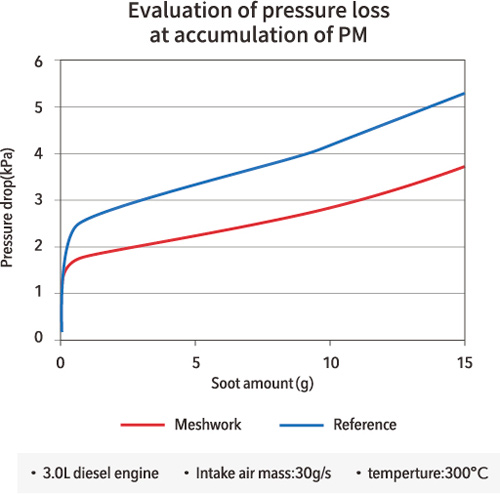

We have made it possible to form mesh type catalyst layer with high gas permeability on the cell wall and to improve PM trap function keeping impact on pressure loss to minimum. Since the catalyst is close to PM because the catalyst layer is on the surface of the cell wall, it is also possible to improve PM burning quality.

(※)DPF recovery

This is the system to clean the filter. When a certain amount of PM accumulates on the filter of DPF, keep the filter at high temperature by forcibly injecting fuel and raise the temperature of the exhaust gas in order to prevent filter from clogging.

"As Meshwork Catalyst keeps the pressure loss lower at accumulation of PM compared to the existing DPF catalyst, it is estimated that the Meshwork Catalyst can reduce 7% of fuel consumption compared to the existing catalyst when the cycle of PM trapping and recovery is repeated 1,000 hours with pressure loss value as a threshold."

"Meshwork Catalyst can reduce 68% of PN(Particle Number, the number of PM) compared to it of existing DPF catalyst."

※"Meshwork Catalyst" is a technical name, not a product name.