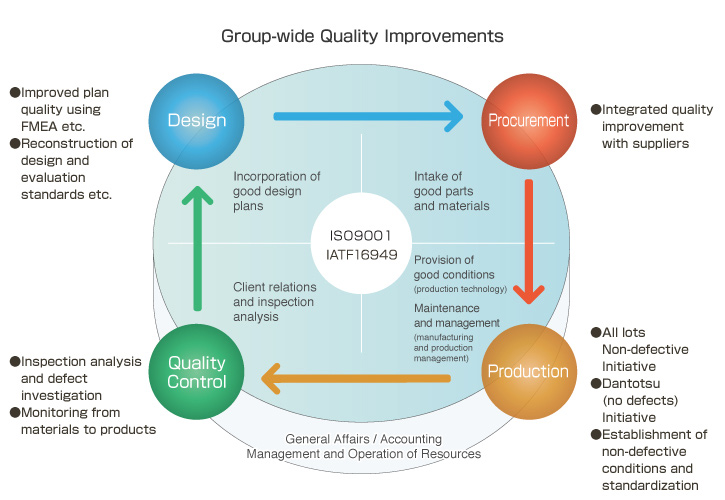

Group companies actively introduce unique manufacturing and high-tech technologies to the production line in efforts to achieve high-quality, low cost product creation from the R&D stage. All employees participate in improvement activities such as the Dantotsu (Zero defects) Initiative.

※ISO9001 is only applicable to CATALER JAPAN

※ISO9001 is only applicable to CATALER JAPANWe meet customer needs as a dedicated partner in the automotive field and various other industrial sectors through extensive activities ranging from the R&D of basic technology, to technical proposals, production technology development, and assistance in preparation for mass-production.

We conduct extensive R&D activities ranging from the development of basic technology for materials used in products, to evaluation test-ing using actual products. Cataler thoroughly evaluates the ideal specifications for each customer's needs from a performance, cost and quality perspective.

We develop production technology for the realization of high-quality, low cost products using unique know-how, by thoroughly isolating issues at the development and prototyping stage, and through evaluation of processes and equipment.

Customers are guaranteed absolute quality by production technology based on sufficient validation and daily improvements at the manu-facturing site.

We guarantee quality that exceeds customer expectations through activities including Factory Floor Quality Patrols, the Dantotsu (zero defect) Initiative, and QC Circles. Moreover, Cataler has established a quality assurance system guaranteeing uniform product quality through the application of identical manufacturing processes at our bases around the world.

※ISO9001 is only applicable to CATALER JAPAN(as of 2017)

※ISO9001 is only applicable to CATALER JAPAN(as of 2017)

●Quality confirmation of incoming materials

●Cross check

In-house metal substrates

●PGM solution analysis

●Quality confirmation of in-house materials

In-house powder

●Property measuring

Slurry

●Dimension measuring

●Precious metal quantitative analysis

●Activity evaluation testing

Final product inspection

●Customer delivery, Dantotsu Initiative

●All lots Non-defective Initiative

Shipment

Factory Floor Quality Patrols

Review of each site and its products

Dantotsu Initiative

Aiming for zero defects in each process through cross-division improvement activities

Regular inspection of overseas bases

Inspection analysis in Indonesia

QC Circle Activities

All employees participate in QC circle activities aimed at improving quality.

QC Circle Shizuoka Region Satsuki Championship

Global QC Circle Championship