Aftertreatment technology to comply with "Euro 6", the emission regulations

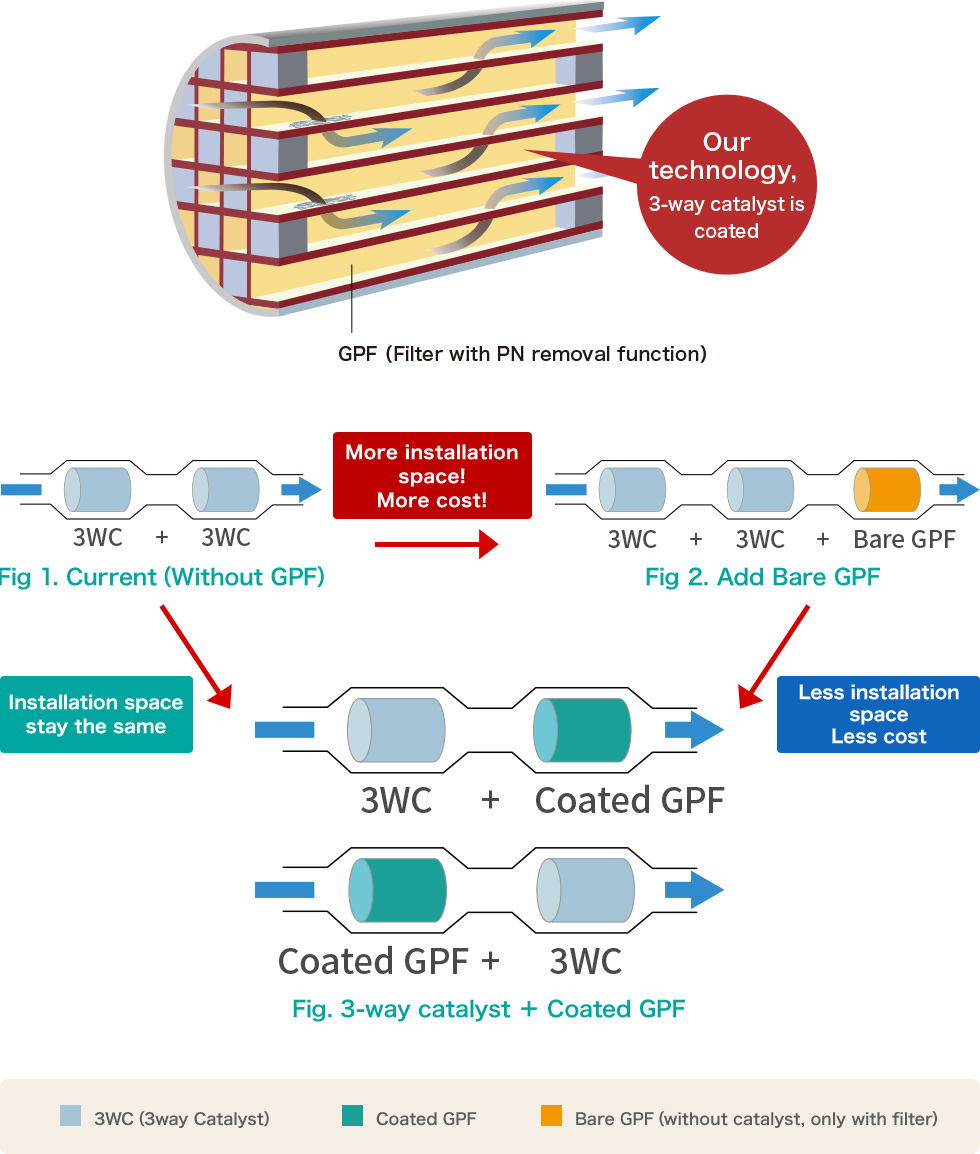

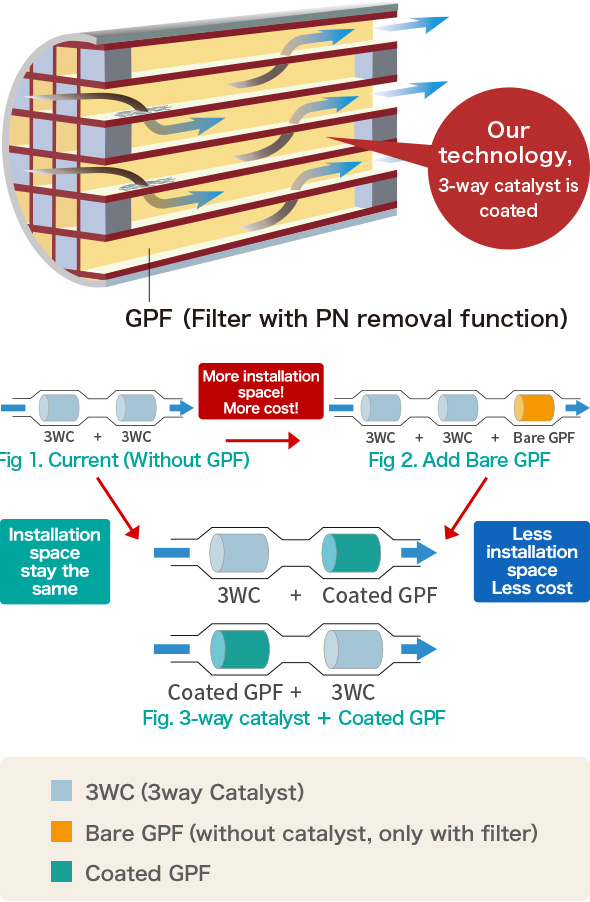

The Gasoline Particulate Filter(GPF) coated with 3-way catalyst purifies exhaust substances and controls emission of the particulate matter(PM) with the high level aftertreatment technology that is required to comply with Euro 6 regulations in Europe.

HOME > Automotive Engineering Exposition 2017 > Coated GPF

Vehicle emissions control regulates upper limit of pollutant emission such as "Carbon monoxide(CO)", "Nitrogen oxide(NOx)", hydrocarbon and black exhaust that are from engine of cars and motorcycles.

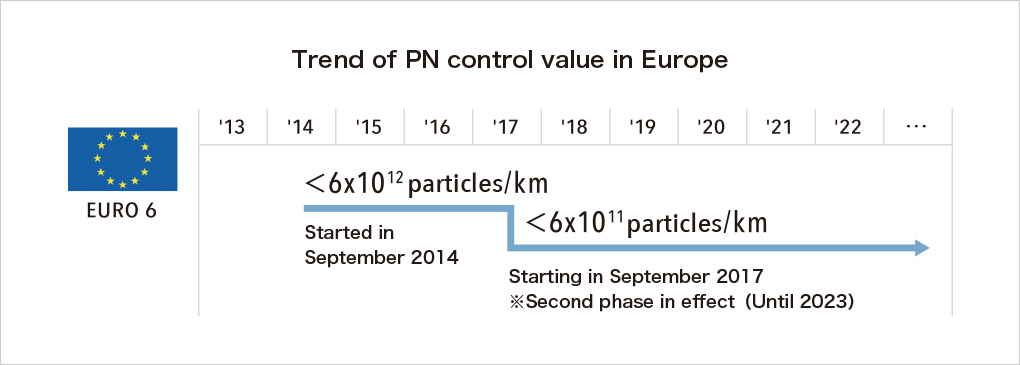

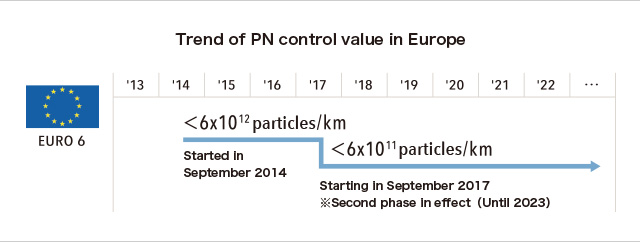

The regulation called "EURO6" that regulates emission control of the air pollutant substances from vehicles has been enforced by EU, European Union since September 1st, 2014. Particularly, control value of emission amount of "Particulate matter (PM)" and "Nitrogen oxide (NOx) are strict in EURO6. The new cars sold in EU has to clear the control value in EURO 6 since January 1st, 2015.

EURO6 d-TEMP which is stricter emission standard will be introduced from September 2017 in order to strengthen control value of "Particle number of exhaust particulate(PN). "Particulate matter (PM)" from car engine has been controlled by "emission weight" but the emission weight of ultra fine particles that is easy to be taken into human bodies and concerned about affecting health is difficult to be reflected in numerical value. So "PN control" that regulates particles by emission number is introduced.

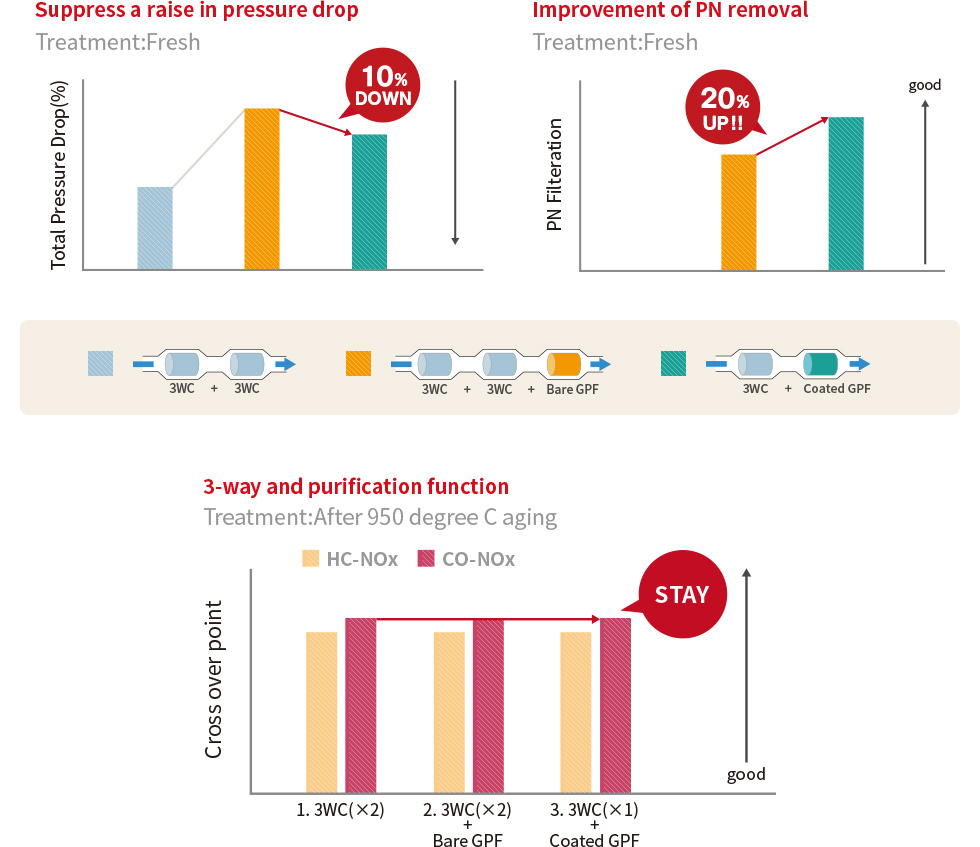

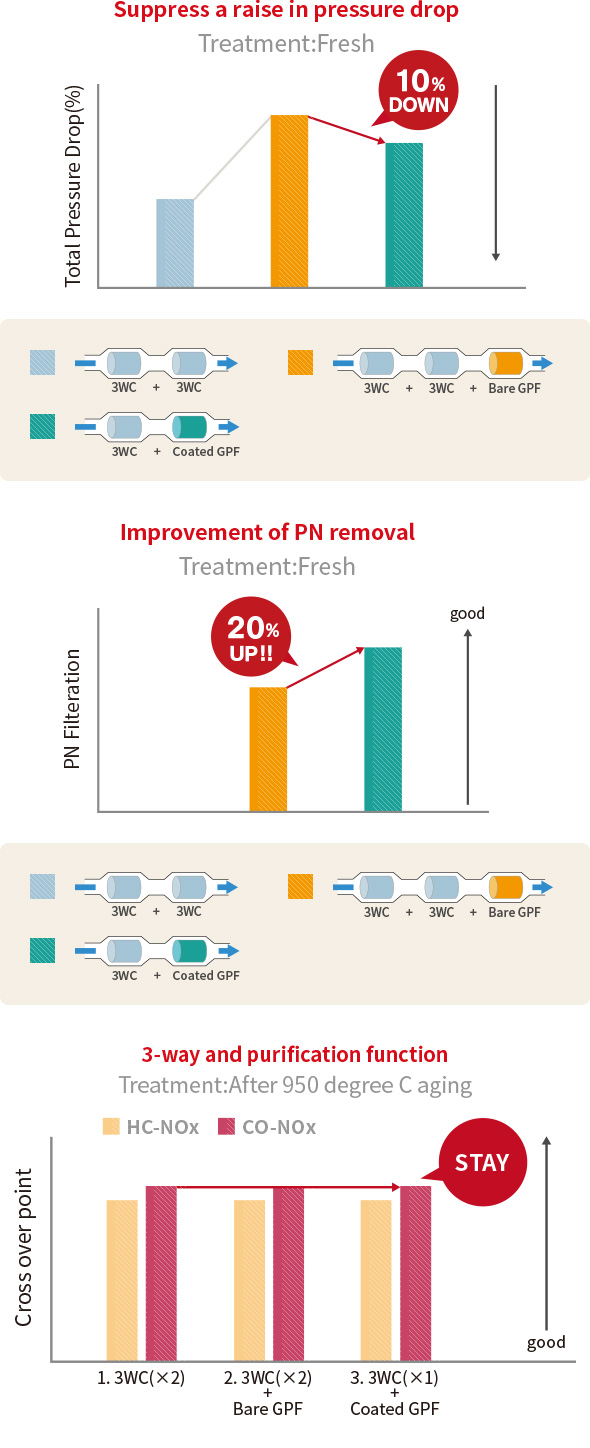

The PN (Particle number of exhaust particulate) regulations sets a limit to the number of fine particulates contained in the gas emissions, unlike the PM(Particulate matter) regulations that controls the weight of particulates. "Gasoline Particulate Filter(GPF)" is then expected to be a means to satisfy PN regulations But the installation of a GPF will just cause the increase in the total cost and occupy the more space for fitting it. (Fig. 2: Add Bare GPF) Then, what we are now developing is a "Coated GPF " that has the functions of both a GPF and a 3-way catalyst.

It can be installed to replace either one of the two of existing 3-way catalyst that are normally mounted at the underfloor and just beneath the gasoline-engine per vehicle, it'll help keep the vehicle's total cost low and save the limited installation space. (Fig. 3: 3-way catalyst + Coated GPF)

Day by day our technology to coat 3-way catalyst on GPF has been improving and developed from various angles. Followings are actual status of "Suppression of pressure drop raise", "Improvement of PN(Particulate number) removal" and "Compatibility of 3-way purification function."